Tool chain analysis & documentation

Tool chain analysis shows strengths and weaknesses

of tool chains, and documents

them in a standard compliant way

Challenges

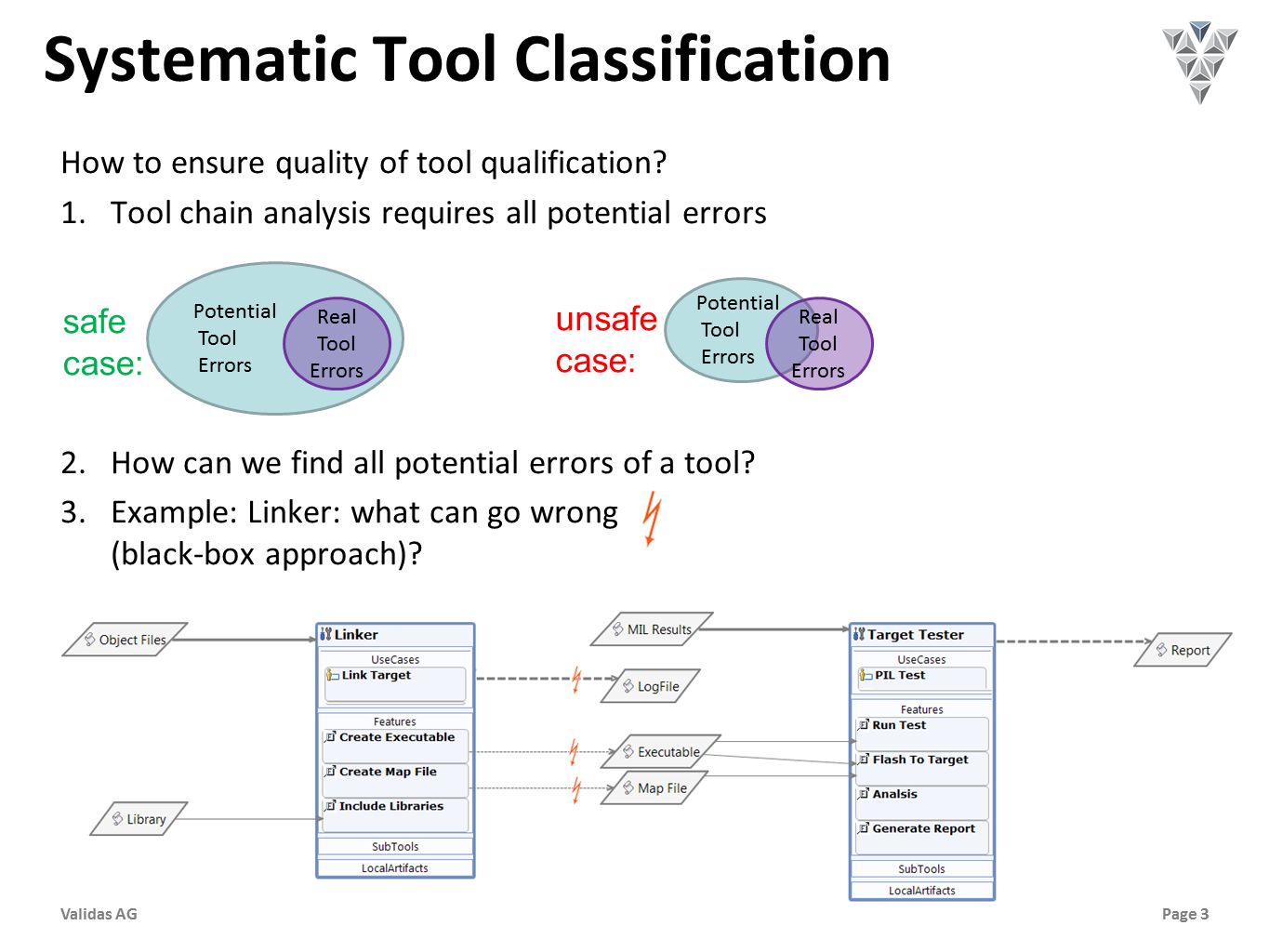

Tool chains for developing systems are becoming ever more complex and thus increasingly difficult to understand and analyze. To safely apply tool chains, first the strengths and weaknesses must be determined, i.e. the tools must be classified.

The classification of the tools depends on their usage in the tool chain.

Safety standards such as ISO 26262, IEC 61508, EN 50128, DO-178C or DO-330, require classification of all the tools used and their validation. This is achieved either by a qualification or by the use of guidelines that define safe use of the tools.

Services

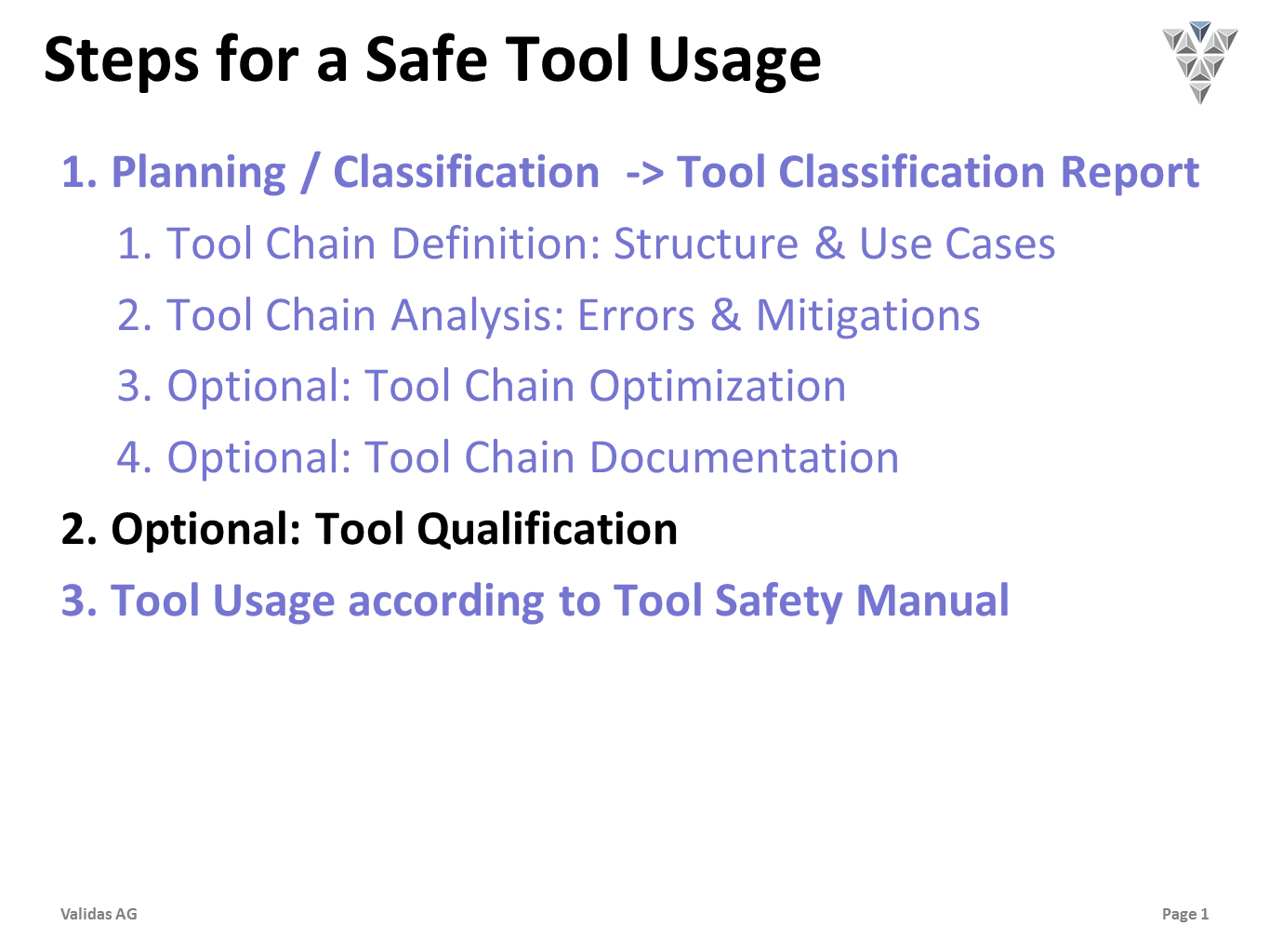

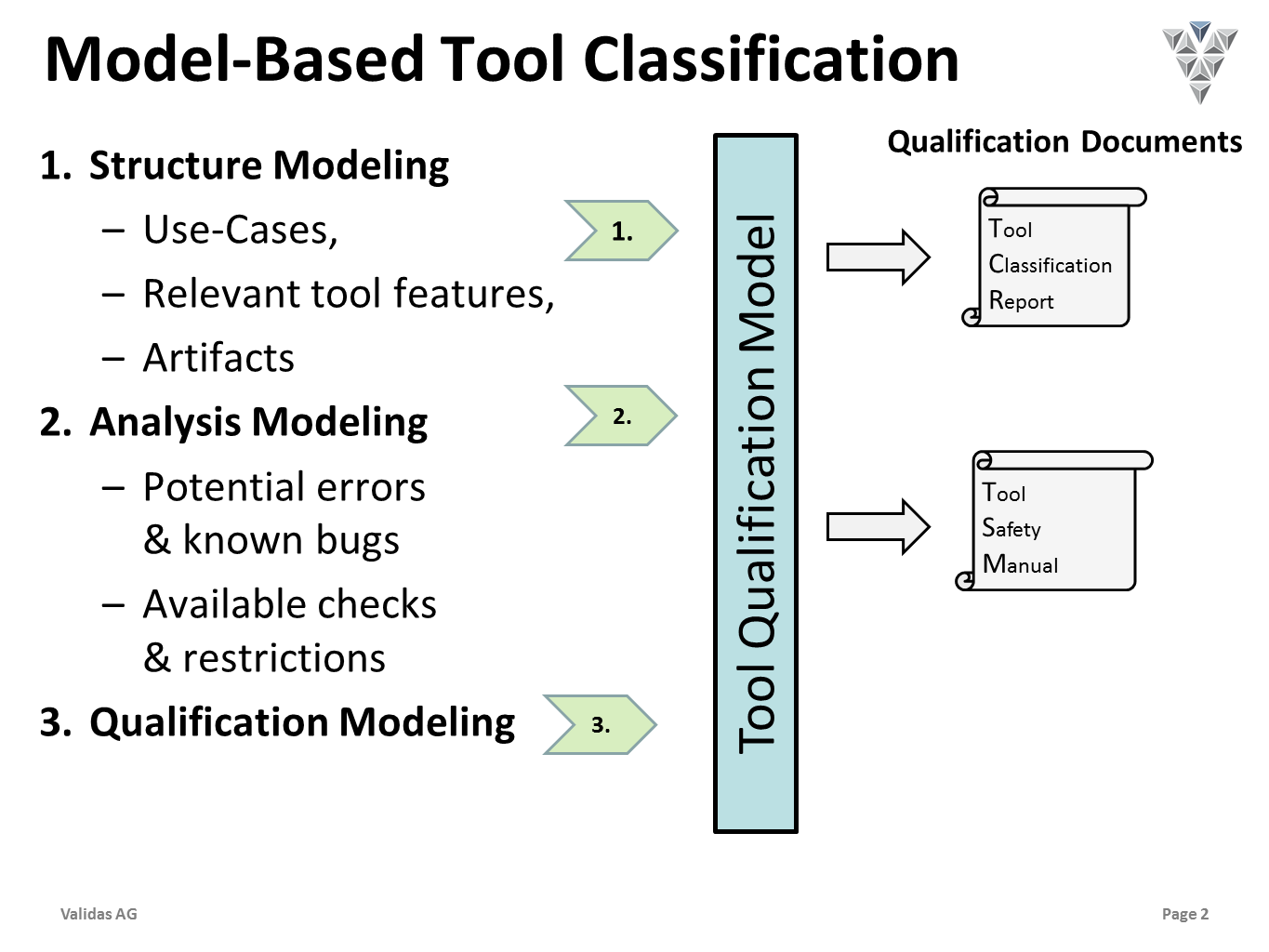

We use a model-based approach to analyze, document and qualify tool chains. The modeling takes place in three steps:

- Creation of the structure view with tools and artifacts

- Creation of the analysis view with potential errors and measures for error detection and avoidance

- Creation of the qualification model with test cases and test results

The models are automatically analyzed (e.g., by calculating the tool confidence level (TCL) or by calculating the impact of tools). The required documents are generated automatically.

We support you in tool chain analysis with the following activities:

- Acquisition and documentation of processes and tools

- Conformity check to ISO 26262 and other standards

- Classification of tool chain:

- Creation of a model (structure, analysis, qualification if required)

- Analysis of models

- Generation of the required documents: Tool Classification Report, Tool Safety Manual, Checklists for execution

- Analysis of known tool errors

- Suggestions for optimizing the tool chain: Minimization of qualification costs vs. costs for safe usage

Example project: Automotive development tool chain

In cooperation with Infineon, we have analyzed a tool chain with 37 tools for the development of ECU software for the highest safety level.

Thereby, the qualification demand could be reduced to one tool by the introduction of suitable measures. The independently performed Confirmation Review showed high quality of the generated documentation and proved itself as problem-free.

How we support you

- Acquisition and documentation of your tool chain

- Creation of a systematic, detailed error model

- Tuning of measures to detect and avoid the modeled errors

Read also

Your benefits

- Detailed Tool Classification Reports together with Tool Safety Manuals

- Maintainable documentation of your tool chain (by generation from a redundancy-free model)

- By systematic modeling, you get neutral justifiable Tool Classification Levels (TCL)

- Precise requirements for the qualification of critical tools

- Low maintenance effort in case of reclassification due to changes

„The Validas model-based approach reduced our certification efforts for the tool chain“

Dr. Rafael Zalman (Senior Principal Functional Safety Development, Infineon Technologies AG )

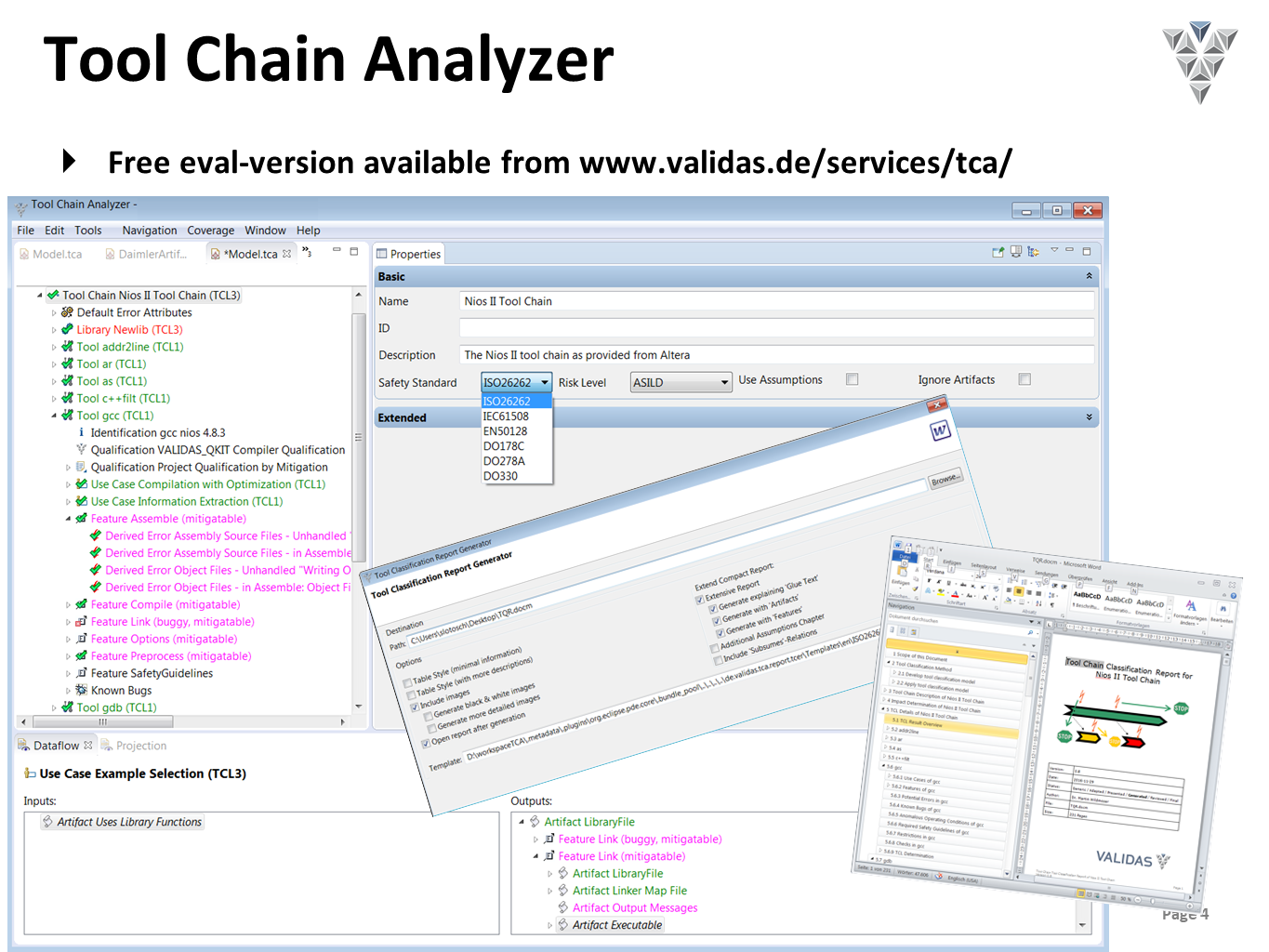

Tool Chain Analyzer

Our Tool Chain Analyzer (TCA) is the tool for modeling and analyzing tools and tool chains. The TCA covers all qualification-relevant aspects of tools.

If you are interested in our product, feel free to schedule a Tool Readiness Check.

Click the following link for a list of tools that we have successfully analyzed and classified.

You want to know more?

Do you want to analyze and document your tool chains with us?

Robert Reitmeier

Tel +49 (89) 5388669-14

E-Mail